Unit 4 - Food preparation

4.4.2. Methods of food preparation (Tips for texture‐modified foods cooking)

4.4.4. Alternative technologies (high‐pressure, hydrodynamic pressure, pulsed electric field, plasma, ultrasound treatment, 3D printing technology)

-

Recently, alternative technologies, including those involving the use of high‐pressure, hydrodynamic pressure, pulsed electric field (PEF), plasma, ultrasound, and irradiation, have been applied to modify the texture (for example, hardness, adhesiveness, cohesiveness), sensory characteristics (aroma and flavor), and to maintain the nutritional value and extend the shelf life of an array of food materials (Jin, Yu, & Gurtler, 2017; Yoshioka et al., 2016).

Non-thermal technologies are of special interest for their ability to preserve color, texture, taste, nutrients, and nutritional density of foods.

High‐pressure treatment

HPP can be used to modify the texture of meat and meat products. HPP at ≥300 MPa could be an alternative to produce meat‐based dysphagia foods. High hydrodynamic pressure (HDP) processing is a novel technology that allows high‐pressure shockwave to pass through water to tenderize vacuum‐packaged meat.

Pulsed electric field

PEF treatment is another interesting technology that can be used to modify the texture of food. PEF at higher frequencies and lower pulse numbers could lead to a decrease in the water loss, but to an increase in the water‐holding capacity of meat upon cooking.

Ultrasound

US is another efficient technology that can be used to improve the texture of protein gel. US has been noted to be capable of reducing the hardness of starch‐based foods to the lowest level (level 4) and is therefore a recommended technique to improve the texture of carbohydrate‐based foods for dysphagic patients.

3D printing technology

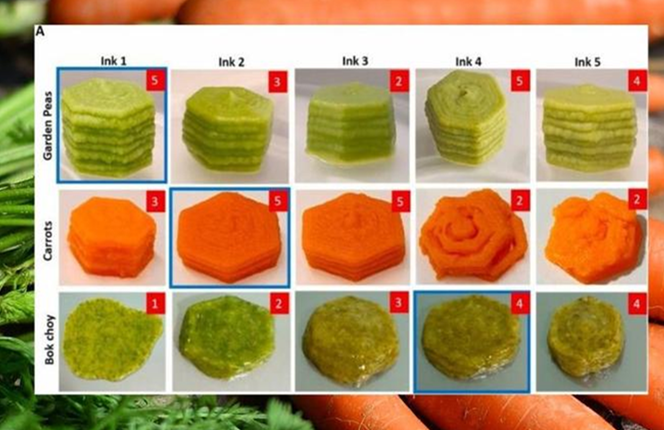

Recently, three‐dimensional (3D) printing

technology has been used to produce foods with a variety of texture

from various raw material sources

3D printing has been used in the past to help elderly patients with dysphagia - difficulty swallowing or chewing - by creating inks made from puréed food and extruding them into a shape that resembles the real dish, like carrots or chicken, to make it more visually appealing.

Kouzani et al. used this method to 3D print a

tuna fish consisting of tuna, pumpkin, and beetroot purees. The

method reduced the design and fabrication time and cost, decreased

the dependency on a skilled cook, and enhanced the visual appearance,

consistency and repeatability of the foods produced that could

potentially be enjoyed by people with dysphagia who require pureed

food.

However, while the benefits include a shorter time to fabricate foods in a more appetizing texture and shape, these freeze-dried powders and dehydrated food inks often need to be stabilized with a lot of food additives, like hydrocolloids, to ensure a smooth print process.

This can change the aroma, taste, and texture of 3D printed food, which makes it much less appetizing to dysphagia patients, as you can imagine, and can lead to issues like malnutrition.

(Source: Pant et al., 2021)

Source: